Welcome!

Our group investigates the design and manufacture of self-assembled and crystalline materials using innovative approaches for process control, integration, and model-based optimization.

Meet our group members, read more about our research, browse our publications, check the news, or join us!

People

Richard Lakerveld

Principal Investigator

Email: r.lakerveld@ust.hk

Room: CYT2003

Phone: (852) 3469 2217

Richard Lakerveld is an Associate Professor and Associate Head in the Department of Chemical and Biological Engineering (CBE) at The Hong Kong University of Science and Technology (HKUST). He joined the CBE department of HKUST in October 2014 as an Assistant Professor and was promoted to Associate Professor in 2020. He was an Assistant Professor at Delft University of Technology for 2 years before joining the faculty of HKUST. Prior to that, he worked for 2 years as Postdoctoral Associate at the Process Systems Engineering Laboratory of the Massachusetts Institute of Technology in the group of Paul Barton. At MIT, he worked on plant-wide control of continuous pharmaceutical manufacturing and on optimal control of directed self-assembly. He received his chemical engineering education from Delft University of Technology where he obtained both his MSc (with honors track) and PhD degree cum laude. His PhD research involved the development of a task-based design approach for solution crystallization processes under supervision of Johan Grievink, Peter Jansens, and Herman Kramer. Furthermore, he was the recipient of an NWO Veni Award in 2013, which is an early career award from the Dutch Science Foundation. His other personal awards include a VNCI award, the Novartis-MIT Enabling Control System Award, and five GRF Awards from Hong Kong's Science Foundation, which are competitive personal grants aimed at supporting cutting-edge research. He also received the School of Engineering Teaching Award for undegraduate teaching and was awarded the Best Teaching Award in an MSc programs twice. He is a member of the 2019 Class of Influential Researchers of the journal Industrial & Engineering Chemistry Research and he is the Topic Coordinator in Pharmaceutical Engineering in the editorial board of Chemical Engineering Research and Design (Elsevier). His research interests are in the field of Process Systems Engineering with a focus on the design and manufacture of crystalline and self-assembled materials. When time permits, he likes to take his bike for a road trip or spend some time on the football pitch.

Jiatao Li

Postgraduate Student

Jiatao joined the Lakerveld Lab in September 2022. He completed his undergraduate studies in Chemical Engineering and Technology at the Guangdong University of Technology, China. He worked on organic fluorescent materials during his undergraduate studies. Afterwards, he completed his Master degree in Chemical and Biomolecular Engineering at HKUST in 2022 where he worked on anti-solvent cocrystallization in the Lakerveld Lab. He is currently developing novel methods to design advanced crystalline drug formulations to mitigate low aqueous solubility. During the spare time, he likes watching movies, swimming, playing badminton, hiking, and enjoying delicacies.

Yunlong Wang

Postgraduate Student

Yunlong joined the Lakerveld Lab in September 2022 as an MSc student. He graduated from Beijing University of Chemical engineering in 2019 with a Bachelor degree in Chemical Engineering and Technology. Afterwards, he obtained his MSc degree from the Department of Chemical and Biological Engineering in HKUST in early 2022 and was awarded with an entrance scholarship. He then joined the Lakerveld Lab as a PhD student in 2023. He is working on the modelling and control of MSMPR crystallizers. In his leisure time, he enjoys watching movies and swimming.

Rasmus Overgaard

Postgraduate Student

Rasmus joined the Lakerveld Lab in September 2023. He completed his undergraduate studies in Chemical Engineering and Biotechnology at the University of Southern Denmark (Denmark) in June 2023. During his undergraduate studies, he worked on a research project about nucleation kinetics and crystal characterization and spent a term as an undergraduate exchange student at the University of Waterloo (Canada). He graduated with an MPhil degree in Summer 2025 and is now continuing as a PhD student. He is working on elucidating the effects of impurities on protein crystallization. During his free time, he enjoys travelling and exploring, watching football, and listening to music.

Mohammad Arkannia

Postgraduate Student

Mohammad joined the Lakerveld Lab in September 2025 as a PhD student within the Dual Degree SUT–HKUST program. He received his BSc in Chemical Engineering from the University of Tehran and his MSc in Energy Engineering from Sharif University of Technology. His master’s thesis focused on optimizing ion-exchange resin regeneration in water treatment systems. He is currently working on pharmaceutical cocrystallization processes in flow systems. In his spare time, he enjoys watching movies and football matches—and even more, playing football.

Alumni

- Dr. Ruipeng Chen (PhD, now research engineer at Xtalpi) [Thesis]

- Dr. Yu Gao (PhD and PD, now postdoctoral associate at The University of Colorado Boulder) [Thesis]

- Junhao Gu (MPhil, now PhD student at UC Irvine) [Thesis]

- Dr. Dishika Gupta (PhD)

- Gabriela Daisy Hadiwinoto (MPhil and RA, now PDEng trainee at Delft University of Technology) [Thesis]

- Cheuk Hei (Matthew) Ho (MPhil) [Thesis]

- Xiao Hua (MPhil, now MSc student in Finance at City University of Hong Kong) [Thesis]

- Dr. Fatemeh (Maryam) Khodadadian (PhD@TU Delft, now research engineer at ASML)[Thesis]

- Dr. Soojin Kwon (PhD, now research engineer at SK Innovation) [Thesis]

- Dr. Fei Li (PD, now research engineer at BASF)

- Dr. Nethrue Pramuditha Mendis (PhD and PD, now postdoctoral associate at The University of Sheffield) [Thesis]

- Dr. Po Sang Lo (PhD)[Thesis]

- Dr. Kiran Mathew Thomas (PhD, now consultant at IRESC) [Thesis]

- Dr. Madiha Nisar (PD, now Scientist at Pharmaxis, Australia)

- Dr. Baggie Waponde Nyande (PhD, Principal at Divvflow Systems) [Thesis]

- Dr. Jiayuan Wang (PhD, now Associate Professor at Zhejiang University of Technology) [Thesis]

- Dr. Xiaojin Xu (PhD, now postdoctoral associate at the Hong Kong Productivity Council)

Research

1. Pharmaceutical crystallization

Crystallization is a crucial unit operation for many chemical processes. For example, a well-designed crystallization process enables intermediate compounds and active pharmaceutical ingredients with a high purity and stable crystalline solid state to be separated and purified in a single step in the pharmaceutical industry. Intrinsic quality attributes of crystals such as solid-state form, shape, and size distribution typically have a substantial impact on downstream processing and final product efficacy. A long-standing challenge in the field is to design and operate industrial crystallizers in such a way that crystals with desired quality attributes are produced in a single step. Furthermore, the performance and sustainability of solution crystallization processes depends on the choice of solvents. Another challenge in the field is to select optimal mixtures of solvents, which not only support efficient crystallization, but also enable optimal and sustainable operation of the process as a whole including unit operations for reaction, extraction, and distillation. More recent challenges include alignment with data-driven concepts such as quality-by-design and an expanding scope of crystallization in pharmaceutical industry towards larger biopharmaceuticals. In our research group we exploit general concepts from process intensification and the current transition from batch to continuous manufacturing in the pharmaceutical industry to address those challenges from a different angle.

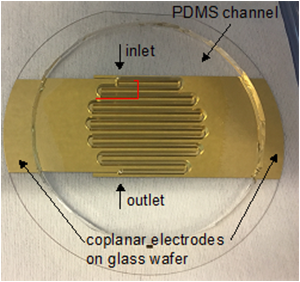

Electric-field-assisted protein crystallization

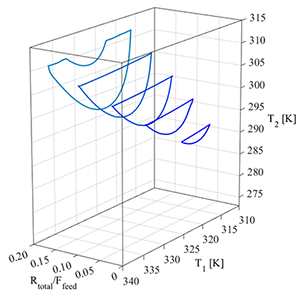

Model-based design spaces

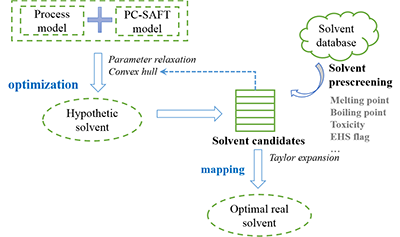

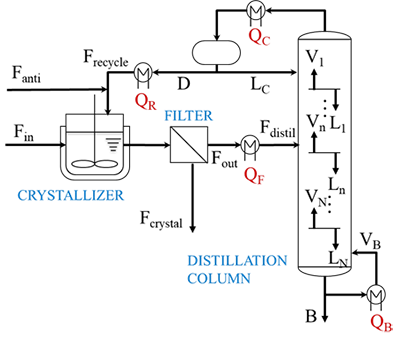

Integrated solvent and process design [27]

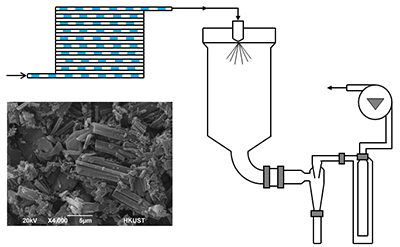

Integrated continuous manufacturing of carrier-free inhalable drugs [36]

CFD analysis of a novel tubular crystallizer [45]

Continuous process optimization [38]

2. Control and optimization of directed self-assembly

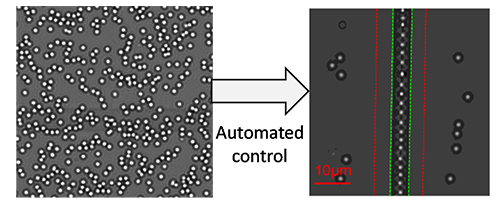

Materials with nano- and micro-scale structures have important applications in many engineering disciplines such as tissue engineering, computing, diagnostics, advanced functional materials, and chemical processing. To obtain the desired functionality and to avoid defects, the manufacture of such materials requires precise control over the formation of tiny structural features. Self-assembly is the association of molecules or particles into structures driven by non-covalent interaction forces. Self-assembly has great potential as a manufacturing technology as it proceeds spontaneously and, if the interaction forces can be well controlled, it allows for up to molecular spatial resolution. Two general challenges can be identified when harnessing self-assembly as synthesis method for advanced materials. First, non-covalent interaction forces need to be designed such that the material is thermodynamically stable in the desired structure. Second, once a desired structure has been identified, a suitable assembly process needs to developed to guide the self-assembly process. We have addressed the former challenge in the area of self-assembled DNA tiles using a novel optimization-based approach. The latter challenge is generally complicated by the stochastic nature, tendency for kinetic trapping, and lack of actuation of self-assembly systems. External fields can be used to manipulate the self-assembly process; a process which is often referred to as ‘directed’ self-assembly. We have developed novel automated control strategies for directed self-assembly of colloidal particles in microfluidic devices using electric fields as actuators, which has been published in a series of papers.

Automated control of directed self-assembly

Featured on Lab on a Chip cover

Publications

Recent Journal Publications (Google Scholar):

- Nyande, B.W.; Diab, S.; Yao, H.; Lakerveld, R.; Nagy, Z.K. Crystallization in the presence of impurities: mechanisms, models and controls. Chem. Eng. Res. Des. 2025, 221, 525-546.(link) (Editor's Choice – CHERD September Issue)

- Yuan, M.; Wang, J.; Lakerveld, R.; Chen, M.; Wang, T.; Wang, N.; Huang, X.; Hao, H. Advanced particle technologies in the preparation of dry powders for inhalation. Particuology. 2025, 102, 118-140. (link)

- Chen, M.; Huang, X.; Lakerveld, R.; Yuan, M.; Zhang, Y.; Lamichhane, S.; Luo, Q.; Ren, J.; Wang, T.; Wang, N.; Hao, H. Computational fluid dynamics simulation of the hydrodynamic and particle suspension performance of a novel channel impeller. Powder Technol. 2025, 458, 120994. (link)

- Gupta, D.; Mak, A.T.C.; Lakerveld, R. Intensified Solid-State Transformation During Anti-Solvent Cocrystallization in Flow. Chem. Eng. Process. 2025, 208, 110108. (link)

- Wu*, H.; Xu*, X.; Wei, B.; Lakerveld, R. Entropy-Driven Self-Assembly of DNA Origami Isomers. Small Structures 2024, 5(12), 2400220. (link)

- Lo, P.S.; Nisar, M.; Lakerveld, R. Temperature Cycling Induced Deracemization of p-Synephrine in the Presence of Degradation. ASC Omega 2024, 9(40), 41936-41943.(link) [.pdf (open access)]

- Nyande, B.W.; Nagy, Z.K.; Lakerveld, R. Data-driven identification of crystallization kinetics. AIChE J. 2024, e18333.(link) [.pdf (open access)]

- Mendis, N.P.; Lakerveld, R. An In Vitro Model for Cocrystal Dissolution with Simultaneous Surface and Bulk Precipitation. Mol. Pharmaceutics 2023, 20(11), 5486–5499. (link)

- Mendis, N.P.; Li, J.; Lakerveld, R. Integrated Selection of Coformers, Solvents, and Operating Conditions for Optimal Process and Product Performance of Pharmaceutical Cocrystals. Ind. Eng. Chem. Res. 2023, 62(33), 13081–13095. (link)

- Mendis, N.P.; Wang, J.; Lakerveld, R. A Workflow for Crystallization Process Design with Simultaneous Process Optimization and Solvent Selection based on the Perturbed-Chain Statistical Associating Fluid Theory. Chem. Ing. Tech. 2023, 95(3), 334-343. (link)

- Gupta, D.; Nyande, B.W.; Mathew Thomas, K.; Li, F.; Mak, A.T.C.; Lakerveld, R. Induced-Charge Electroosmosis for Rapid Mixing of Reactive Precipitation Systems to Obtain Small and Uniform Particles. Chem. Eng. Res. Des. 2023, 190, 715-729. (link)

- Wang, J.; Song, Z.; Lakerveld, R.; Zhou, T. Solvent Selection for Chemical Reactions toward Optimal Thermodynamic and Kinetic Performances: Group Contribution and COSMO-based Modeling. Fluid Phase Equilibria 2023, 564, 113623.(link) (Special Issue on Group contribution-based property prediction)

- Yi, Q.; Dai, X.; Park, B.M.; Gu, J.; Luo, J.; Wang, R.; Yu, C.; Kou, S.; Huang*, J.; Lakerveld*, R.; Sun*, F. Directed assembly of genetically engineered eukaryotic cells into living functional materials via ultrahigh-affinity protein interactions. Sci. Adv. 2022, 8(44), eade0073.(link) [.pdf (open access)] (* corresponding authors) (highlighted by The Scientist)(HKIE best paper award in materials 2023)

- Nyande, B.W.; Mathew Thomas, K.; Takarianto, A.A.; Lakerveld, R. Control of crystal size distribution in batch protein crystallization by integrating a gapped Kenics static mixer to flexibly produce seed crystals. Chem. Eng. Sci. 2022, 263, 118085.(link)

- Gao, Y.; Liu, K.; Lakerveld, R.; Ding, X. Staged Assembly of Colloids Using DNA and Acoustofluidics. Nano Lett. 2022, 22(17), 6907-6915.(link)

- Mendis, N.P.; Wang, J.; Lakerveld, R. Simultaneous Solvent Selection and Process Design for Continuous Reaction–Extraction–Crystallization Systems. Ind. Eng. Chem. Res. 2022, 61(31), 11504–11517. (link)

- Kwon, S.; Lakerveld, R. Impact of Cooling Profile on Batch Emulsion Solution Crystallization. Ind. Eng. Chem. Res. 2022, 61(30), 11108–11115. (link) (Highlighted by OPR&D)

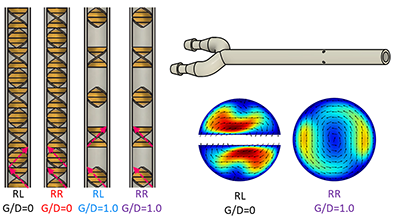

- Mathew Thomas*, K.; Nyande*, B.W.; Lakerveld, R. Design and Characterization of Kenics Static Mixer Crystallizers. Chem. Eng. Res. Des. 2022, 179, 549-563. (link) (* contributed equally) (Editor's Choice; Special Issue on Advances in Continuous Crystallization)

- Wong, S.N.; Weng, J.; Ip, I.C.W.; Chen, R.; Lakerveld, R.; Blagden, N.; Scowen, I.J.; Chow, S.F. Rational Development of a Carrier-Free Dry Powder Inhalation Formulation for Respiratory Viral Infections via Quality by Design: A Drug-Drug Cocrystal of Favipiravir and Theophylline. Pharmaceutics. 2022, 14(2), 300. (link open access)

- Kwon, S.; Mathew Thomas, K.; Lakerveld, R. Integrated membrane emulsification and solution cooling crystallization to obtain a narrow and predictable crystal size distribution. Chem. Eng. Process. 2022, 171, 108751. (link)

- Xuan, B.; Chen, Y.C.S.; Wong, K.C.; Chen, R.; Lo, P.S.; Lakerveld, R.; Tong, H.H.Y.; Chow, S.F. Impact of cocrystal solution-state stability on cocrystal dissociation and polymorphic drug recrystallization during dissolution Int. J. Pharm. 2021, 610, 121239. (link)

- Kang, H.; Lin, T.; Xu, X.; Jia*, Q.S.; Lakerveld*, R.; Wei*, B. DNA dynamics and computation based on toehold-free strand displacement. Nat. Commun. 2021, 12, 4994. (open access link) (* corresponding authors)

- Capdevila-Echeverria, J.; Wang, J.; Lakerveld, R.; Ter Horst, J.H. Process modeling and optimization of continuous chiral resolution by integration of membrane and crystallization technologies. J. Membr. Sci. 2021, 632, 119359. (link)

- Nyande*, B.W.; Mathew Thomas*, K.; Lakerveld, R. CFD Analysis of a Kenics Static Mixer with a Low Pressure Drop under Laminar Flow Conditions. Ind. Eng. Chem. Res. 2021, 60(14), 5264–5277.(link) (* contributed equally)

- Mathew Thomas, K.; Kwon, S.; Lakerveld, R. Continuous Protein Crystallization in Mixed-Suspension Mixed-Product-Removal Crystallizers. Cryst. Growth Des. 2021, 21(2), 757-769.(link)

- Chen, R.; Weng, J.; Chow, S.F.; Lakerveld, R. Integrated Continuous Crystallization and Spray Drying of Insulin for Pulmonary Drug Delivery. Cryst. Growth Des. 2021, 21(1), 501–511. (link)

- Fajrial, A.K.; Liu, K.; Gao, Y.; Gu, J.; Lakerveld, R.; Ding, X. Characterization of Single-Cell Osmotic Swelling Dynamics for New Physical Biomarkers. Anal. Chem. 2021, 93(3), 1317-1325.(link)

- Wang, J.; Cao, W.; Zhu, L.; Wang, J.; Lakerveld, R. Emulsion-assisted cooling crystallization of ibuprofen. Chem. Eng. Sci. 2020, 226, 115861.(link)

- Gao, Y.; Nyande, B.W.; Lakerveld, R. Open-loop control of directed self-assembly of colloidal particles in a microfluidic device. Comput. Chem. Eng. 2020, 139, 106837. (link)

- Wang, J.; Li, J.; Cao, W.; Zhu, L.; Lakerveld, R. An ion-specific electrolyte non-random two-liquid segment activity coefficient model with improved predictive capabilities for aqueous electrolyte solutions. Fluid Phase Equilibria 2020, 517(1), 112605.(link)

- Wang, J.; Zhu, L.; Lakerveld, R. A Hybrid Framework for Simultaneous Process and Solvent Optimization of Continuous Anti-Solvent Crystallization with Distillation for Solvent Recycling. Processes 2020, 8(1), 63-74.(link) (open-access) (Feature Paper)

- Mathew Thomas, K.; Lakerveld, R. An Airlift Crystallizer for Protein Crystallization. Ind. Eng. Chem. Res. 2019, 58(44), 20381-20391.(link) (among the five most-read articles of the journal in November 2019)

- Hadiwinoto, G.D.; Kwok, P.C.L.; Tong, H.H.Y.; Wong, S.N.; Chow, S.F.; Lakerveld, R. Integrated Continuous Plug-Flow Crystallization and Spray Drying of Pharmaceuticals for Dry Powder Inhalation. Ind. Eng. Chem. Res. 2019, 58(36), 16843-16857.(link) (Special issue featuring the 2019 class of influential researchers)

- Gao, Y.; Lakerveld, R. Feedback Control for Shaping Density Distributions of Colloidal Particles in Microfluidic Devices. Lab Chip 2019, 19(13), 2168-2177. (link)(highlighted on the Inside front cover)

- Weng, J.; Wong, S.N.; Xu, X.; Xuan, B.; Wang, C.; Chen, R.; Sun, C.C.; Lakerveld, R.; Kwok, P.C.L.; Chow, S.F. Cocrystal Engineering of Itraconazole with Suberic acid via Rotary Evaporation and Spray Drying. Cryst. Growth. Des. 2019, 19(5), 2736-2745. (link)

- Gao, Y.; Lakerveld, R. Gain Scheduling PID Control for Directed Self-assembly of Colloidal Particles in Microfluidic Devices. AIChE J. 2019, 65, e16582. (link)

- Khodadadian, F.; De La Garza, F.G.; Van Ommen, J. R.; Stankiewicz, A. I.; Lakerveld, R. The Application of Automated Feedback and Feedforward Control to a LED-based Photocatalytic Reactor. Chem. Eng. J. 2019, 362, 375-382. (link)

- Gao, Y.; Lakerveld, R. Feedback Control for Defect-free Alignment of Colloidal Particles. Lab Chip 2018, 18, 2099-2110. (link)

- Li, F.; Lakerveld, R. Electric-field-assisted protein crystallization in continuous flow. Cryst. Growth Des. 2018, 18(5), 2964-2971. (link)

- Wang, J.; Fei, L.; Lakerveld, R. Process Intensification for Pharmaceutical Crystallization. Chem. Eng. Process. 2018, 127, 111-126. (link)(Invited - Special Issue on Process Intensification for Advanced Materials Synthesis)(among the most read papers of the journal for 12+ months)

- Nisar, M.; Sung, H.H.Y.; Puschmann, H.; Lakerveld, R.; Haynes, R.; Williams, I.D. 11-Azaartemisinin cocrystals with preserved lactam: acid heterosynthons. CrystEngComm 2018, 20(9), 1205-1219. (link)(Inside cover)

- Wang, J.; Lakerveld, R. Integrated Solvent and Process Design for Continuous Crystallization and Solvent Recycling using PC-SAFT. AIChE J. 2018, 64(4), 1205–1216. (link)

- Khodadadian, F.; De Boer, M.W.; Poursaeidesfahani, A.; Van Ommen, J. R.; Stankiewicz, A. I.; Lakerveld, R. Design, characterization and model validation of a LED-based photocatalytic reactor for gas phase applications. Chem. Eng. J. 2018, 333, 456-466. (link)

- Hadiwinoto, G.D.; Kwok*, P.C.L.; Lakerveld*, R. A review on recent technologies for the manufacture of pulmonary drugs. Ther. Deliv. 2017, 9(1), 47-70.(link)

- Li, F.; Lakerveld, R. The influence of alternating electric fields on protein crystallization in microfluidic devices with patterned electrodes in a parallel-plate configuration. Cryst. Growth Des. 2017, 17(6), 3062–3070. (link)

- Wang, J.; Lakerveld, R. Continuous Membrane-Assisted Crystallization to Increase the Attainable Product Quality of Pharmaceuticals and Design Space for Operation. Ind. Eng. Chem. Res. 2017, 56(19), 5705–5714.(link)

- Gao, Y.; Mi, Y.; Lakerveld, R. An optimization-based approach for structural design of self-assembled DNA tiles. AIChE J. 2017, 63(6), 1804-1817.(link)

- Mesbah, A.; Paulson, J.;Lakerveld, R.; Braatz, R.D. Model Predictive Control of an Integrated Continuous Pharmaceutical Manufacturing Pilot Plant. Org. Process Res. Dev. 2017, 21(6), 844–854. (link)

- Khodadadian, F.; Poursaeidesfahani, A.; Li, Z.; Van Ommen, J. R.; Stankiewicz, A. I.; Lakerveld, R. Model-based Optimization of a Photocatalytic Reactor with Light-Emitting Diodes. Chem. Eng. Technol. 2016, 39(10), 1946-1954. (link)

Before joining HKUST

- Kacker, R.; Salvador, P.M.; Sturm, G.S.J.; Stefanidis, G.D.; Lakerveld, R.; Nagy, Z.K.; Kramer, H.J.M. Microwave Assisted Direct Nucleation Control for Batch Crystallization: Crystal Size Control with Reduced Batch Time. Cryst. Growth Des. 2016, 16(1), 440-446. (link)

- Ramaswamy, S.; Lakerveld, R.; Barton, P.I.; Stephanopoulos, G. Controlled Formation of Nanostructures with Desired Geometries: Part 3. Dynamic Modeling and Simulation of Directed Self-Assembly of Nanoparticles through Adaptive Finite State Projection. Ind. Eng. Chem. Res. 2015, 54(16), 4371-4384. (link)

- Lakerveld, R.; Benyahia, B.; Heider, P.L.; Zhang, H.; Wolfe, A.; Testa, C.J.; Ogden, S.; Hersey, D.R.; Mascia, S.; Evans, J.M.B.; Braatz, R.D.; Barton, P.I. The application of an automated control strategy for an integrated continuous pharmaceutical pilot plant. Org. Process Res. Dev. 2015, 19(9), 1088-1100. (link)

- Lakerveld, R.; Van Krochten, J.J.H.; Kramer, H.J.M. An air-lift crystallizer can suppress secondary nucleation at a higher supersaturation compared to a stirred crystallizer. Cryst. Growth Des. 2014 , 14(7), 3264-3275. (link)

- Lakerveld, R.; Sturm, G.S.J.; Stankiewicz, A.I.; Stefanidis, G.D. Integrated design of microwave and photocatalytic reactors. Where are we now? Curr. Opin. Chem. Eng. 2014 5,37-41. (link)

- Zhang, H.; Lakerveld, R.; Heider, P.L.; Tao, M.; Su, M.; Testa, C.; D'Antonio, A.; Barton, P.I.; Braatz, R.D.; Trout, B.L.; Myerson, A.S.; Jensen, K.F.; Evans, J.M.B. Application of continuous crystallization in an integrated continuous pharmaceutical pilot plant. Cryst. Growth Des. 2014, 14(5), 2148-2157. (link)

- Heider, P.L.; Born, S.C.; Basak, S.; Benyahia, B.; Lakerveld, R.; Zhang, H.; Hogan, R.; Buchbinder, L.; Wolfe, A.; Mascia, S.; Evans, J.M.B.; Jamison, T.F.; Jensen, K.F. Development of a Multi-Step Synthesis and Workup Sequence for an Integrated, Continuous Manufacturing Process of a Pharmaceutical. Org. Process Res. Dev. 2014, 18(3), 402-4093. (within the Top 20 of most read articles of February 2014 in OPRD) (link)

- Lakerveld, R.; Benyahia, B.; Heider, P.L., Zhang, H.; Braatz, R.D.; Barton, P.I. Averaging Level Control to Reduce Off-Spec Material in a Continuous Pharmaceutical Pilot Plant. Processes 2013, 1(3), 330–348. (Feature paper)(link)

- Mascia, S.; Heider, P.L.; Zhang, H.; Lakerveld, R.; Benyahia, B.; Barton, P.I.; Braatz, R.D.; Cooney, C.L.; Evans, J.M.B.; Jamison, T.F.; Jensen, K.F.; Myerson, A.S.; Trout, B.L. End-to-End Continuous Manufacturing of Pharmaceuticals: Integrated Synthesis, Purification, and Final Dosage Formation. Angew. Chem. Int. Ed. 2013, 52(47), 12359-12363. ('Hot' paper, highlighted in Nature) (link)

- Lakerveld, R.; Benyahia, B.; Braatz, R.D.; Barton, P.I. Model-based design of a plant-wide control strategy for a continuous pharmaceutical plant. AIChE J. 2013, 59(10), 3671–3685. (link)

- Lakerveld, R.; Stephanopoulos, G.; Barton, P. I. A master-equation approach to simulate kinetic traps during directed self-assembly. Journal of Chemical Physics 2012, 136 (18). (link)

- Soare, A.; Lakerveld, R.; van Royen, J.; Zocchi, G.; Stankiewicz, A. I.; Kramer, H. J. M. Minimization of Attrition and Breakage in an Airlift Crystallizer. Industrial Engineering Chemistry Research. 2012, 51 (33), 10895-10909. (link)

- Benyahia, B.; Lakerveld, R.; Barton, P. I. A Plant-Wide Dynamic Model of a Continuous Pharmaceutical Process. Industrial Engineering Chemistry Research. 2012, 51 (47), 15393-15412. (link)

- Lakerveld, R.; Verzijden, N. G.; Kramer, H.; Jansens, P.; Grievink, J. Application of Ultrasound for Start-Up of Evaporative Batch Crystallization of Ammonium Sulfate in a 75-L Crystallizer. AIChE Journal 2011, 57 (12), 3367-3377. (link)

- Lakerveld, R.; Kramer, H. J. M.; Stankiewicz, A. I.; Grievink, J. Application of generic principles of process intensification to solution crystallization enabled by a task-based design approach. Chemical Engineering and Processing 2010, 49 (9), 979-991.(link)

- Lakerveld, R.; Kuhn, J.; Kramer, H. J. M.; Jansens, P. J.; Grievink, J. Membrane assisted crystallization using reverse osmosis: Influence of solubility characteristics on experimental application and energy saving potential. Chemical Engineering Science 2010, 65 (9), 2689-2699.(link)

- Lakerveld, R.; Kramer, H. J. M.; Jansens, P. J.; Grievink, J. The application of a task-based concept for the design of innovative industrial crystallizers. Computers & Chemical Engineering 2009, 33 (10), 1692-1700.(link)

- Kuhn, J.; Lakerveld, R.; Kramer, H. J. M.; Grievink, J.; Jansens, P. J. Characterization and Dynamic Optimization of Membrane-Assisted Crystallization of Adipic Acid. Industrial Engineering Chemistry Research. 2009, 48 (11), 5360-5369.(link)

- Lakerveld, R.; Bildea, C. S.; Almeida-Rivera, C. P. Exothermic isomerization reaction in a reactive flash: Steady-state behavior. Industrial Engineering Chemistry Research. 2005, 44 (10), 3815-3822.(link)

Book chapters:

- Lakerveld, R.; Benyahia, B. Process Control. Chapter 4. The Handbook of Continuous Crystallization (editors: Nima Yazdanpanah & Zoltan Nagy), Royal Society of Chemistry, 2020, ISBN: 978-1788012140, (forthcoming: 21 February 2020).

- Stelzer, T.; Lakerveld, R.; Myerson, A.S. Process Intensification in Continuous Crystallization. Chapter 10. The Handbook of Continuous Crystallization (editors: Nima Yazdanpanah & Zoltan Nagy), Royal Society of Chemistry, 2020, ISBN: 978-1788012140, (forthcoming: 21 February 2020).

- Kramer, H.J.M.; Lakerveld, R. Selection and design of industrial crystallizers. Chapter 7 in Handbook of Industrial Crystallization, 3rd edition, Cambridge University Press, 2019, ISBN: 9781139026949.

- Lakerveld, R.; Control system implementation and plant-wide control of continuous pharmaceutical manufacturing pilot plant (end-to-end manufacturing process). Chapter 16 in Process Systems Engineering for Pharmaceutical Manufacturing. Elsevier, 2018, ISBN: 978-0-444-63963-9.

- Lakerveld, R.; Heider, P. L.; Jensen, K. D.; Braatz, R. D.; Jensen, K. F.; Myerson, A. S.; Trout, B. L.; End-to-End Continuous Manufacturing: Integration of Unit Operations. Chapter 13 in Continuous Manufacturing of Pharmaceuticals. Wiley-Blackwell, 2017, ISBN: 978-1-119-00132-4.

- Khodadadian, F.; Nasalevich, M.; Kapteijn, F.; Stankiewicz, A.I.; Lakerveld, R.; Gascon, J. Photocatalysis: Past achievements and future trends. Chapter 8. RSC Green Chemistry. Volume 2016-January, Issue 47, 2016, Pages 227-269.

Selected papers in peer-reviewed conference proceedings:

- Mendis, N.P.; Lakerveld, R. A Thermodynamic Approach for Simultaneous Solvent, Coformer, and Process Optimization of Continuous Cocrystallization Processes. Computer-Aided Chemical Engineering, 2022, in press.

- Mendis, N.P.; Wang, J.; Lakerveld, R. A Thermodynamic Approach for Simultaneous Solvent and Process Design of Continuous Reactive Crystallization with Recycling. Computer-Aided Chemical Engineering 48, 2020, 805-810.

- Gao, Y.; Lakerveld, R. Automated open-loop control of directed selfassembly with multiple electrokinetic actuators in microfluidic devices. Computer-Aided Chemical Engineering 46, 2019, 43–48.

- Nyande, B.W.; Gao, Y.; Lakerveld, R. A dynamic model for automated control of directed self-assembly of colloidal particles at low densities. Computer-Aided Chemical Engineering 46, 2019, 1783–1788.

- Gao, Y.; Lakerveld, R. Experimental Validation of Scheduled PID Control for Directed Self-Assembly of Colloidal Particles in Microfluidic Devices. Proceedings of the 13th International Symposium on Process Systems Engineering (PSE 2018), July 1 - July 4, 2018, San Diego, CA, USA, 2455–2460.

- Wang, J.; Lakerveld, R. Integrated Solvent and Process Optimization Using PC-SAFT for Continuous Crystallization with Energy-intensive Solvent Separation for Recycling. Proceedings of the 13th International Symposium on Process Systems Engineering (PSE 2018), July 1 - July 4, 2018, San Diego, CA, USA, 1051–1056.

- R. Lakerveld, B. Benyahia, P.L. Heider, H. Zhang, A. Wolfe, C.J. Testa, S. Ogden, D.R. Hersey, S. Mascia, J.M.B. Evans, R.D. Braatz, P.I. Barton, The Application of an Automated Plant-wide Control Strategy for a Continuous Pharmaceutical Pilot Plant. Proceedings of the 2014 American Control Conference, June 04-June 06, 2014, Portland, Oregon, USA, 3512-3517.

- R. Lakerveld, G. Stephanopoulos, P.I. Barton, Robust fabrication of non-periodic nanoscale systems via directed self-assembly. Computer-Aided Chemical Engineering 29, 2011, 1603-1607.

- R. Lakerveld, H.J.M. Kramer, P.J. Jansens, J. Grievink, The application of a task-based concept for design of innovative industrial crystallizers. PSE 2009 Conference Proceedings, Salvador, Brazil, 2009.

- R. Lakerveld, H.J.M. Kramer, A.I. Stankiewicz, P.J. Jansens, J. Grievink, Opportunities for process intensification in crystallization: application of air-mixed devices, ultrasound & membranes. EPIC 2009 Conference Proceedings, Venice, Italy, 2009.

- R. Lakerveld, H.J.M. Kramer, P.J. Jansens and J. Grievink, The Application of a Task Based Design Approach to Solution Crystallization. FOCAPD Conference Proceedings, Breckenridge, Colorado, United States, 2009.

- R. Lakerveld, H.J.M. Kramer, P.J. Jansens, J. Grievink, A task based design approach for solution crystallization. BIWIC 2008 Conference Proceedings, Magdeburg, Germany, 2008, 95-102.

- R. Lakerveld, H.J.M. Kramer, P.J. Jansens, J. Grievink, A Task Based Design Approach for Solution Crystallization. 17th International Symposium on Industrial Crystallization Conference Proceedings, Maastricht, The Netherlands, 2008, 27-34.

- R. Lakerveld, H.J.M. Kramer, P.J. Jansens, J. Grievink, Solution Crystallization in a Bubble Column. Optimization of the task: Crystal Growth, 17th International Symposium on Industrial Crystallization Conference Proceedings, Maastricht, The Netherlands, 2008, 819-826.

- R. Lakerveld, J. Kuhn, M.A. Bosch, H.J.M. Kramer, P.J. Jansens, J. Grievink, Membrane Assisted Evaporative Crystallization: Optimization of Task Supersaturation Generation, 17th International Symposium on Industrial Crystallization Conference Proceedings, Maastricht, The Netherlands, 2008, 827-834.

- R. Lakerveld, P.G. Verzijden, H.J.M. Kramer, P.J. Jansens, J. Grievink, The Application of Ultrasound for Seeding Purposes Optimization of the task: Nucleation, 17th International Symposium on Industrial Crystallization Conference Proceedings, Maastricht, The Netherlands, 2008, 835-842.

- R. Lakerveld, H.J.M. Kramer, P.J. Jansens, J. Grievink, The application of a task-based concept for the design of innovative industrial crystallizers. 18th European Symposium on Computer Aided Process Engineering Conference Proceedings, Lyon, France 2008, 103-108.

- R. Lakerveld, A.N. Kalbasenka, H.J.M. Kramer, P.J. Jansens, J. Grievink, The application of different seeding techniques for solution crystallization of ammonium sulphate. BIWIC 2007 Conference Proceedings, Cape Town, South Africa, 2007, 221-228.

- R. Lakerveld, M.E. Djatmiko, H.J.M. Kramer, P.J. Jansens, J. Grievink, Task based design techniques for solution crystallisation processes: application to a bubble column setup. BIWIC 2006 Conference Proceedings, Delft, The Netherlands, 2006, 114 – 121.

News

Dec, 2025: Richard receives the Best Teaching Award of the MSc BEHI program (2024-25 academic year). Congratulations!

Sep, 2025: Richard delivers an invited lecture on static mixer crystallizers at the 2025 BIWIC conference in Tianjin.

Sep, 2025: MSc student Yuchen joins the Lakerveld Lab for an independent research project. Welcome!

Sep, 2025: Postgraduate student Mohammad joins the Lakerveld Lab. Welcome!

Aug, 2025: Rasmus successfully defends his MPhil thesis and becomes PhD student. Congratulations!

Aug, 2025: Baggie's review paper on crystallization in the presence of impurities has been published in ChERD and is the Editor's Choice of the CHERD September Issue. Congratulations! (link)

Apr, 2025: A collaborative review paper on advanced particle technologies in the preparation of dry powders for inhalation has been published in Particuology. Congratulations! (link)

Apr, 2025: Richard delivers a CCEB department seminar at Nanyang Technological University on pharmaceutical crystallization.

Mar, 2025: A collaborative paper on a CFD study of a new type of impeller for improved particle suspension has been published in Powder Technology. Congratulations! (link)

Jan, 2025: Yunlong passes his PhD qualifying examination. Congratulations!

Oct, 2024: Xiaojin's and Holly's paper on entropy-driven self-assembly of DNA origami isomers has been published in small structures. Congratulations! (link) [.pdf (open access)]

Sep, 2024: Victor's paper on a new crystallization-based deracemization process for the chiral compound synephrine is published in ACS Omega. Congratulations! (link) [.pdf (open access)]

Sep, 2024: MSc students Yuan, Xiang, Lin, and Yihuan join the Lakerveld Lab for an independent research project. Welcome!

Aug, 2024: Dishika successfully defends her PhD thesis. Congratulations!

Jul, 2024: Pramuditha joins the University of Sheffield as Postdoctoral Associate. Congratulations!

Jul, 2024: Richard delivers an invited talk at Tianjin University on Novel process concepts and computational tools for pharmaceutical crystallization.

Jun, 2024: The group celebrates the end of the academic year with two(!) nice lunches!

Jun, 2024: Victor successfully defends his PhD thesis. Congratulations!

Feb, 2024: Baggie's paper on data driven identification of crystallization kinetics has been published in AIChE Journal. The work shows how one can obtain functional forms of kinetic expressions to model crystallization processes from data alone. The work was a collaboration with Purdue University. Congratulations! (link open access)

Dec, 2023: Richard delivers a keynote lecture on Advanced Pharmaceutical Manufacturing at the World Intelligent Manufacturing Conference 2023 in Nanjing.

Nov, 2023: Pramuditha and Baggie present their work at the 2023 AIChE Annual Meeting in Orlando, Florida!

Sep, 2023: Pramuditha's paper presenting a new model for predicting the in vitro dissolution-supersaturation-precipitation behavior of pharmaceutical cocrystals has been published in Molecular Pharmaceutics. We apply a population balance-based model, as commonly used in industrial crystallization, to the gastrointestinal tract (a stomach can be a crystallizer as well!) to predict how precipitation of the stable drug lowers the drug concentration of supersaturating drug delivery systems. Such method can be important for the design of medicine based on pharmaceutical cocrystals to effectively overcome a low aqueous solubility of a pure drug. Congratulations! (link)

Sep, 2023: MSc student Chenming joins the Lakerveld Lab for an independent research project. Welcome!

Sep, 2023: Postgraduate students Rasmus and Yunlong join the Lakerveld Lab. Welcome!

Aug, 2023: Xiaojin successfully defends his PhD thesis. Congratulations!

Aug, 2023: Pramuditha's and Jiatao's paper presenting a new mathematical framework for optimization of a cocrystallization process with simultaneous solvent and coformer selection when considering both process and product performance has been published in Industrial Engineering Chemistry Research. The work also includes experimental verification and reveals a new solvent from predictive thermodynamic modeling for a standard pharmaceutical cocrystallization system with superior performance compared to those solvents used in the literature. It stresses the great potential of combined process optimization and predictive thermodynamic modeling for pharmaceutical crystallization. Congratulations! (link)

Aug, 2023: The group receives an ASPIRE grant to develop new collaborations in the area of modeling and control for advanced pharmaceutical manufacturing with NTU Singapore!

Jun, 2023: The group defeats an angry mob of zombies (in virtual reality that is...) and enjoys an authentic Sri Lankan dinner in central Hong Kong (as verified by a qualified Lakerveld Lab member) to close the academic year!

Feb, 2023: The group receives a grant of HK$1,139,650 from Hong Kong's Innovation Technology Fund to investigate new approaches to antibody crystallization. Crystallization of therapeutic proteins can potentially offer a drastically improved way of purifying therapeutic proteins with the promise of more affordable high-quality biological drugs in the future. Congratulations!

Jan, 2023: Pramuditha successfully defends his PhD thesis. Congratulations!

Jan, 2023: Pramuditha's paper presenting a workflow for simultaneous solvent selection and optimization of crystallization process conditions has been publised in a special issue of Chemie Ingenieur Technik. Our aim is simple: suppose you have an organic chemical that you wish to purify with crystallization, but you don't how and you do not have much resources to spend on R&D. If you follow the workflow and run the Matlab functions that we provide, you will know what is a good solvent (mixture), crystallization method, and operating condition. Congratulations! (link)

Jan, 2023: Dishika's paper demonstrating how induced-charge electroosmosis can be used to rapidly mix reactants for reactive crystallization has been published in Chemical Engineering Research & Design. Making small and uniform particles through reactive crystallization is important for many applications in chemical and pharmaceutical industries. Fast mixing is essential for such processes. We present a new type of active mixer based on electroosmosis that can achieve this in a new way. The study involves CFD simulations, mixing experiments, and reactive crystallization experiments. Congratulations! (link)

Nov, 2022: Our recent collaborative work on the directed assembly of genetically engineered eukaryotic cells into living functional materials has been highlighted in an article from The Scientist.

Nov, 2022: Dishika presents her work at the 2022 AIChE Annual Meeting.

Nov, 2022: Soojin's recent paper on membrane-assisted emulsion solution crystallization has been highlighted by a group of experienced industrial researchers in the Highlights from the Literature section of the journal Organic Process Research & Development. This section summarizes remarkable accomplishments from the recent literature with a high potential for future practical applications. Congratulations!

Nov, 2022: Junhao's collaborative paper in which we make living(!!) materials through controlled assembly of genetically engineered yeast cells has been published in Science Advances. The work is a collaboration with the groups of Prof. Fei Sun and Prof. Jinqing Huang at HKUST. Our group developed the microfluidic devices and the electric-field-assisted methodology for the controlled assembly of the cells into structured materials. These living materials can have many new applications in for example chemical separation and biomedical technologies, which is also demonstrated in the paper. Congratulations! (link)

Oct, 2022: Richard's joint perspective paper on solvent design for chemical reactions together with Dr. Teng Zhou (HKUST GZ), Dr. Zhen Song (ECUST), and (Lakerveld-lab-alumnus) Dr. Jiayuan Wang (ZJUT) has been published in a Special Issue of Fluid Phase Equilibria on group contribution-based property prediction. Congratulations! (link)

Sep, 2022: Baggie's, Kiran's, and Abraham's work on a novel method to produce seed protein crystals has been published in Chemical Engineering Science. The work presents an elegant solution based on continuous crystallization for the long-standing problem of how to make high-quality seed crystals for batch protein crystallization. The paper also shows that the method is highly flexible in desiging different seeding policies to shape the crystal size distribution. Congratulations! (50-day free-access link)

Sep, 2022: MSc students Yunlong and Dezhao join the Lakerveld Lab for independent research projects. Welcome!

Sep, 2022: Postgraduate student Jiatao joins the Lakerveld Lab. Welcome!

Aug, 2022: Our collaborative work with Prof. Xiaoyun Ding and Lakerveld-lab-alumnus Dr. Yu Gao at the University of Colorado on the staged assembly of colloids with DNA sticky ends has been published in Nano Letters. Assembling tiny particles with grafted DNA is attractive because the DNA strands can reversibly bind to immobilize a target structure so that one can reliably produce new materials. Many years ago, we tried this with electric fields, but the conditions were not compatible, and we abandoned the idea. This paper shows that with acoustofluidics on the other hand this works very well. A nice illustration also of the fruits of collaborative research. Take a look to know how one can make (reversible!) hotdogs from tiny particles. Congratulations!(link)

Aug, 2022: Baggie successfully defends his PhD thesis. Congratulations!

Aug, 2022: Soojin successfully defends her PhD thesis. Congratulations!

Aug, 2022: Pramuditha's paper demonstrating a new approach for simultaneous solvent selection and design of processes involving reaction, extraction, and crystallization has been published in Industrial & Engineering Chemistry Research. Solvents are often a major source of costs, waste, and safety, health, and environmental concerns in fine-chemical and pharmaceutical industries. Besides, solvents often have a great impact on process performance. Especially for continuous processes, it is important to select solvents that work well throughout the entire process to make these processes more sustainable. Pramuditha's method shows how you can do that with the ePC-SAFT equation of state and numerical optimization for a general class of processes involving a sequence of reaction-extraction-crystallization steps. Congratulations! (link)

Jul, 2022: Soojin's paper investigating the impact of cooling profiles on emulsion solution crystallization has been published in Industrial & Engineering Chemistry Research. This research became possible by extending her earlier work on the integration of membrane emulsification and emulsion solution crystallization. Thanks to the continuous flow mode of the membranes, she could install a tubular crystallizer in between the emulsion-formation and crystallization steps, which allowed rapid and precise control over the initial temperature. Congratulations! (link)

Jul, 2022: The group has been awarded a GRF Research Grant from Hong Kong's University Grants Committee of HK$ 522,000 for investigating novel methods to design advanced crystalline drug formulations to mitigate low aqueous solubility of many drugs so that ultimately medicines can become cheaper and more effective to patients. Congratulations!

Jun, 2022: The group closes the academic year with a nice dinner at St. Barts!

Jun, 2022: Pramuditha presents his work on a novel thermodynamic approach for simultaneous solvent, coformer, and process optimization of continuous cocrystallization processes at PSE 2021!

Jun, 2022: Baggie and Victor win the highly competitive HKUST RedBird Academic Excellence Award for Continuing PhD Students in the 2021/22 Academic Year! Congratulations!

Mar, 2022: Kiran's and Baggie's recent paper has been selected as Editor's Choice in Chemical Engineering Research and Design. Congratulations!

Jan, 2022: Kiran's and Baggie's work (equal contributions) on the application of a new type of static mixer to continuous protein crystallization has been published in a Special Issue on Advances in Continuous Crystallization of the journal Chemical Engineering Research & Design. The work shows that a static mixer with gaps between the mixing elements, positioned in the same flow orientation, can strike a remarkable compromise between a hollow tubular crystallizer and conventional (dense) static mixer. The 'gapped' Kenics static mixer has lower pressure drop and shear, like a hollow tube, but the mixing efficiency of a dense static mixer, which is great for continuous crystallization applications that require a bit more residence time like protein crystallization. The entire device was 3D printed and we have included the STL files of all modules as supporting information so you can print your own modular static mixer (including jacket, tube connectors, etc.) for any application! Congratulations to Kiran and Baggie! (link)

Jan, 2022: Our collaborative work on the development of a new drug-drug cocrystal has been published in Pharmaceutics. Congratulations to Ruipeng and all collaborators! (link (open source))

Dec, 2021: Richard joins the Editorial Board of the journal Chemical and Process Engineering. Congratulations!

Nov, 2021: Soojin's and Kiran's paper on a novel process concept that integrates membrane emulsification and solution crystallization has been published in Chemical Engineering and Processing - Process Intensification. Congratulations!(link)

Nov, 2021: Our collaborative work on the impact of solution-state stability on cocrystal dissociation and polymorphic drug recrystallization with the group of Prof. Aviva Chow at the University of Hong Kong has been published in the International Journal of Pharmaceutics. Congratulations to Ruipeng and Victor and all collaborators for this nice work! (link)

Sep, 2021: Baggie and Kiran receive the Best Poster Award at the ISIC21 for their work on "A 3D-printed Low Pressure-Drop Plug-Flow Crystallizer for Protein Crystallization". Congratulations!

Sep, 2021: Soojin and Baggie present their work at the 21st International Symposium on Industrial Crystallization (ISIC21)!

Aug, 2021: Matthew successfully defends his MPhil thesis. Congratulations!

Aug, 2021: Kiran successfully defends his PhD thesis. Congratulations!

Aug, 2021: Our collaborative work with Tsinghua University on the dynamics of toehold-free strand displacement in DNA self-assembly with potential applications in molecular computing has been published in Nature Communications. Congratulations to Xiaojin and all collaborators! (link)

May, 2021: Bruce, Liangliang, and Abraham successfully complete their individual research project in the group. Well done!

May, 2021: A team of undergraduate students supervised by Richard and Prof. Henry Tong won the Silver Award in the HKUST President's cup for their final year project involving their revolutionary plan to apply continuous manufacturing in the cosmetic industry. Congratulations to Grace, Lia, Maria, and Melody!

Apr, 2021: Our collaborative work on a noval continuous chiral resolution process by integration of membrane and crystallization technologies with University of Strathclyde has been published in Journal of Membrane Science. Congratulations to Jose and Jiayuan! (link)

Mar, 2021: Baggie's and Kiran's paper (equal contributions) on a new type of Kenics static mixer with low pressure drop has been published in Industrial & Engineering Chemistry Research. Static mixers can be used as continuous reactors/crystallizers and are gaining renewed importance with the trend toward continuous processing in fine and pharmaceutical industries. They are attractive due to the absence of moving parts or the need to introduce inert phases to approximate plug-flow conditions. However, pressure drop can be a problem when the residence time is long. For one of our projects, we removed mixing elements from a conventional Kenics static mixer to reduce pressure drop. To our surprise, we noticed that the mixing performance either only slightly degraded or even improved for certain configurations when introduce these gaps, while maintaining or even improving plug-flow behavior. The paper contains a detailed technical analysis of this surprising find. A nice touch of the work is the experimental verification of some of the main conclusions of the work using 3D-printed static mixers. Congratulations!(link)

Jan, 2021: Dishika passes her PhD qualifying examination. Congratulations!

Jan, 2021: Ruipeng successfully defends his PhD thesis. Congratulations!

Jan, 2021: Kiran's and Soojin's work on continuous protein crystallization in MSMPR crystallizers has been published in Crystal Growth and Design. Congratulations! (link)

Dec, 2020: Ruipeng's work on integrated continuous crystallization and spray drying of insulin for pulmonary drug delivery has been published in Crystal Growth and Design. This project was a collaborative project with The University of Hong Kong. Congratulations! (link)

Dec, 2020: Richard joins the editorial board of Chemical Engineering Research and Design. Congratulations!

Nov, 2020: Junhao's collaborative work on the the characterization of Single-Cell Osmotic Swelling Dynamics with collaborators from University of Colorado Boulder (including Lakerveld Lab alumnus Dr. Yu Gao!) has been published in Analytical Chemistry. Congratulations! (link)

Sep, 2020: MSc students Bruce and Liangliang join the lab for individual research projects. Welcome!

Sep, 2020: Ruipeng will present his work on integrated continuous crystallization and spray drying of insulin as an invited talk for a Webinar Series of the European Working Party on Crystallization on Sept 9-11. Join us through the live stream on YouTube to see his and many other great talks. More information can be found here.

Sep, 2020: Madiha accepts a postdoctoral position at the Department of Chemistry. Congratulations!

Aug, 2020: Shiyu, Yao, Ziyang, and Rui successfully completed their individual MSc research project in the group. Congratulations!

Jul, 2020: Richard is promoted to Associate Professor with substantiation. Congratulations!

Jun, 2020: Richard receives the Best Teaching Award of the MSc CBME program (2018-19 academic year). Congratulations!

Jun, 2020: Jiayuan's work on emulsion-assisted cooling crystallization has been published in Chemical Engineering Science. Congratulations!(link)

Apr, 2020: Yu's and Baggie's work on a novel open-loop control strategy for directed self-assembly has been published in computers and chemical engineering. The work is an extended version of the ESCAPE-29 conference paper on the same topic and will be published in a special issue of Computers and Chemical Engineering featuring more extended versions of papers presented at the conference. Congratulations!(link)

Apr, 2020: Jiayuan's and Jintao's work on an novel ion-specific eNRTL-SAC model with improved predictive capabilities for aqueous electrolyte solutions has been published in Fluid Phase Equilibria. Congratulations!(link)

Jan, 2020: Jiayuan's work on simultaneous process and solvent optimization for continuous anti-solvent crystallization with distillation has been published in Processes (open-access) as a Feature Paper in a special issue on process optimization and control. Congratulations! (link)

Nov, 2019: Kiran's paper is among the most read articles from Industrial & Engineering Chemistry Research of the last 30 days. Congratulations!

Nov, 2019: Baggie, Kiran, and Richard present work of the group at the 2019 AIChE Annual Meeting in Orlando, Florida! Richard co-chairs a session on 3D printing.

Oct, 2019: Kiran's paper on protein crystallization in an airlift crystallizer has been published in Industrial & Engineering Chemistry Research. The airlift crystallizer can produce larger crystals with reduced attrition and also can deliver an increased throughput compared to a conventional stirred crystallizer for the studied model protein. The work also shows how 3D printing can be used to fabricate mini-pilot plant equipment rapidly and at low cost. Congratulations! (link)

Oct, 2019: Hongrui joins the lab as visiting exchange student from Tsinghua University. Welcome!

Sep, 2019: Richard has been elected a member of the 2019 Class of Influential Researchers of Industrial & Engineering Chemistry Research (see the editorial note and cover). Gabriela's paper (link) has been included in the corresponding special issue. Congratulations!

Sep, 2019: Richard has been awarded the School of Engineering Teaching Excellence Appreciation Award 2018-2019 (photo!). Congratulations!

Sep, 2019: UG students Sunny and Anshuman join the lab for an independent research project. Welcome!

Sep, 2019: MSc students Shiyu, Yao, Ziyang, and Rui join the lab for independent research projects. Welcome!

Sep, 2019: Postdoctoral associate Madiha joins the Lakerveld Lab. Welcome!

Sep, 2019: Postgraduate students Dishika and Matthew join the Lakerveld Lab. Welcome!

Sep, 2019: NPT magazine highlights this year's ESCAPE conference, which was co-organized by Richard and attended by Baggie. You can read the article here (e-mail registration required) with a photo of all participants enjoying the nice Dutch weather in early Summer.

Sep, 2019: Former MPhil student Junhao joins UC Irvine as a PhD student. Congratulations!

Aug, 2019: No less than four group members (a record!) have passed their PhD qualifying examination. Congratulations to Pramuditha, Soojin, Victor, and Xiaojin and good luck with the next phase as a PhD candidate!

Aug, 2019: Kiran has won a travel grant for the Next-Gen Manufacturing Topical Conference of the 2019 AIChE Annual Meeting in Orlando. The award is being provided kindly by the AIChE Foundation. Congratulations!

Aug, 2019: Gabriela's paper on integrated continuous crystallization and spray drying of pulmonary drugs has been published in Industrial & Engineering Chemistry Research. The collaborative work shows how continuous anti-solvent crystallization can produce crystals in the desired size range for dry powder inhalation in a single step followed by rapid solvent evapoation through spray drying. The novel process is demonstrated for two relevant pulmonary drugs. Congratulations! (link)

Jul, 2019: Junhao successfully defends his MPhil thesis. Congratulations!

Jul, 2019: The group has no less than 5 abstracts accepted for the 2019 AIChE Annual Meeting. Join us in Orlando to hear talks from Kiran, Baggie, and Richard on how to 3D-print innovative crystallization processes, how to used model-based control for directed self-assembly, or how to make pulmonary drugs in a single step without a need for conventional size-correction steps by using a compact and integrated continuous process! Richard will also co-chair a session with exciting talks on 3D printing within the broader topic of smart manufacturing.

Jul, 2019: The group has been awarded a GRF Research Grant from Hong Kong's University Grants Committee of HK$ 695,919 for investigating novel approaches to pharmaceutical crystallization for improved control over crystal size and product uniformity. Congratulations!

Jun, 2019: Yu's paper is featured on the Inside front cover of Lab on a Chip!

Jun, 2019: Baggie presents his research at the ESCAPE-29 conference in Eindhoven. Richard presents a key note lecture based on the work of Gao Yu. You can find the conference proceedings here, which have been co-edited by Richard.

Jun, 2019: Maryam successfully defends her PhD thesis at TU Delft. Congratulations!

Jun, 2019: The 3rd edition of the handbook of industrial crystallization edited by Allan S. Myerson (Massachusetts Institute of Technology), Deniz Erdemir (Bristol-Myers Squibb), and Alfred Y. Lee (Merck & Co., Inc) has been published including a chapter on the selection and design of industrial crystallizers written by Herman Kramer and Richard Lakerveld. link

May, 2019: Yu's paper on a novel automated control method to create specified density distribution of tiny particles in microfluidic devices based on directed self-assembly has been published in Lab on a Chip. Congratulations! The paper marks the latest contribution of a series of papers in which we show how concepts from process control can be combined with microfluidics to enable the defect-free fabrication of structured materials via attractive bottom-up synthesis approaches.(link)

May, 2019: Yi, Xiatong, Yue, Cong, Isaac, and Pasindu all successfully completed an individual research project in our group. Isaac wins the best poster award. Congratulations to all and good luck with future endeavors!

Apr, 2019: The Lakerveld lab (almost) complete a hiking trip to the highest peak of Hong Kong! The trip was followed by a well-deserved and authentic Korean dinner (as verified by two credible and qualified Lakerveld lab members). (photo).

Mar, 2019: A paper co-authored by Ruipeng and Richard on using evaporation and spray drying for cocrystal formation has been published in Crystal Growth and Design. Congratulations! (link)

Feb, 2019: Yu's paper on gain-scheduled feedback control applied to directed self-assembly of colloidal particles has been published in AIChE Journal. Congratulations! (link)

Feb, 2019: Richard co-guest-edited a special issue in the new journal Process Integration and Optimization for Sustainability (Springer) entitled "Process System Engineering for Sustainability in Asia Pacific". Our editorial note can be read here.

Jan, 2019: Yu's and Baggie's papers on automated control of directed self-assembly have been accepted for ESCAPE-29. Congratulations! Make sure to come to the always beautiful Netherlands (Spring time!) to see their work in the emerging theme of CAPE/PSE in hi-tech micro/nano-devices and processes. Richard will deliver the keynote lecture of the theme.

Jan, 2019: Jose joins the Lakerveld Lab as an international exchange student from University of Strathclyde, Glasgow. Welcome!

Dec, 2018: Maryam's paper presenting the first demonstration of how "smart" light sources can be combined with fast process analytical technologies in automated control loops for improved operation of a LED-based photocatalytic reactor has been accepted for publication in Chemical Engineering Journal. Congratulations! (link) (50 days free access via this link!)

Nov, 2018: Former PhD student Dr. Jiayuan Wang starts as a lecturer at Zhejiang University of Technology. Congratulations!

Nov, 2018: Former PhD student Dr. Yu Gao starts as a postdoctoral associate at The University of Colorado Boulder. Congratulations!.

Nov, 2018: Kiran presents his work at the AIChE Annual Meeting in Pittsburgh.

Sep, 2018: MSc students Yi, Xiatong, Yue, and Cong join the Lakerveld Lab for individual research projects. Welcome!

Sep, 2018: We have a vacancy for a postdoctoral associate (see vacancies). Submit your application and join us!

Aug, 2018: Baggie passes his PhD qualifying examination. Congratulations!

Aug, 2018: Jiayuan successfully defends his PhD thesis. Congratulations!

Aug, 2018: Postgraduate students Soojin, Xiaojin, and Pramuditha join the Lakerveld Lab. Welcome!

Aug, 2018: Former MPhil student and research assistant Gabriela joins the Professional Doctorate in Engineering (PDEng) traineeship at Delft University of Technology. Congratulations!

Aug, 2018: Jiayuan finishes his 2-month international exchange at the University of Strathclyde in Glasgow, Scotland.

Jul, 2018: Sherry successfully defends her MPhil thesis. Congratulations!

Jul, 2018: Yu and Jiayuan present their work at the 2018 PSE conference in San Diego, CA, USA!

Jul, 2018: The group has been awarded a GRF Research Grant from Hong Kong's University Grants Committee of HK$ 632,421 for investigating novel approaches to continuous pharmaceutical crystallization. Congratulations!

Jun, 2018: Postgraduate student Ruipeng joins the Lakerveld lab. Welcome!

Jun, 2018: The academic year has been officially closed with......a night of bowling followed by an authentic (as verified by a credible and qualified Lakerveld lab member) Indian dinner! Happy summer to everyone!

Jun, 2018: Yu's paper on automated feedback control for defect-free alignment of colloidal particles via directed self-assembly has been published in Lab on a Chip. Congratulations! (link)

Jun, 2018: Yu and Richard deliver invited lectures at the School of Chemical Engineering of the East China University of Science and Technology on control and optimization of directed self-assembly and pharmaceutical crystallization, respectively.

Jun, 2018: Jiayuan's and Fei's review paper on process intensification for pharmaceutical crystallization is among the most downloaded articles from Chemical Engineering and Processing - Process Intensification in the last 90 days. Congratulations!

Jun, 2018: Read our invited article on pharmaceutical crystallization in Issue 31 of Pharma Focus Asia, a leading pharma magazine in print and digital versions across Asia and rest of the world.

May, 2018: Andrew successfully finishes his 6-month international exchange and is heading back to Tsinghua University, Beijing. Thanks Andrew and good luck wrapping up your studies!

May, 2018: Richard chairs a session and delivers an invited plenary speech at the 2018 International Forum on Crystal Engineering & Smart manufacturing (CESM2018) in Tianjin.

May, 2018: Nicole, Jonathan, Kay, Isaac and Matthew all successfully present the results of their individual undergraduate research project in the Lakerveld Lab to CBE faculty. Congratulations and job well done!

Apr, 2018: Fei's paper on electric-field-assisted protein crystallization in continuous flow has been accepted for publication in Crystal Growth & Design. Congratulations! (link)

Mar, 2018: Jiayuan's and Fei's review paper on process intensification for pharmaceutical crystallization has been accepted for publication in Chemical Engineering Processing: Process Intensification. Congratulations!(link)

Feb, 2018: Yu and Jiayuan have papers accepted for the PSE 2018 conference. Come to San Diego to see their work on automated control of directed self-assembly and integrated process and solvent design for continuous pharmaceutical crystallization!

Feb, 2018: Former postdoc Dr. Fei Li accepts a faculty position at Tianjin University. Congratulations!

Jan, 2018: The Lakerveld lab complete a hiking trip followed by a well-deserved dinner in Lamma Island (photo).

Jan, 2018: Gao Yu successfully defends his PhD thesis. Congratulations!

Jan, 2018: A paper co-authored by Richard on 11-Azaartemisinin cocrystals has appeared in CrystEngComm. You can find our paper here.

Jan, 2018: Richard delivers invited lectures on industrial crystallization of (bio)pharmaceuticals at Tianjin University and Hebei University of Technology.

Dec, 2017: Andrew joins the Lakerveld lab from Tsinghua University Beijing as an exchange postgraduate student for 6 months. Welcome!

Oct, 2017: Gabriela's review paper on recent technologies for the manufacture of pulmonary drugs has been accepted for publication in Therapeutic Delivery. Congratulations!(link)

Oct, 2017: Jiayuan's paper on integrated solvent and process design for continuous crystallization and solvent Recycling using PC-SAFT has been accepted for publication in AIChE Journal. Congratulations!(link)

Sep, 2017: Maryam's paper on the design, characterization and model validation of a LED-based photocatalytic reactor for gas phase applications has been accepted for publication in Chemical Engineering Journal. Congratulations!(link)

Sep, 2017: MSc student Jintao joins the Lakerveld Lab for an individual research project. Welcome!

Sep, 2017: Undergraduate students Nicole, Isaac, and Matthew join the Lakerveld Lab for individual research projects. Welcome!

Aug, 2017: Fei, Yu, Jiayuan, and Gabriela present their work at the 17th Congress of the Asian Pacific Confederation of Chemical Engineering (APCChE2017).

Aug, 2017: Postgraduate students Baggie and Junhao join the Lakerveld lab. Welcome!

Aug, 2017: A book chapter co-authored by Richard on integrated continuous pharmaceutical manufacturing has been published by Wiley. Congratulations!

Jul, 2017: The academic year has been officially closed with a delicious summer BBQ (photo)!

Jul, 2017: Gabriela successfully defends her MPhil thesis on a novel continuous crystallization process for pulmonary drugs. Congratulations!

Jul, 2017: The group has been awarded a GRF Research Grant from Hong Kong's University Grants Committee of HK$ 582,000 for investigating novel methods for automated control of directed self-assembly processes. Congratulations!

May, 2017: A paper co-authored by Richard and co-workers from MIT and UC Berkeley on model predictive control of an integrated continuous pharmaceutical manufacturing pilot plant has appeared in Organic Process Research & Development. You can find our paper here.

May, 2017: Fei's paper on electric-field-assisted protein crystallization has been accepted for publication in Crystal Growth & Design. Congratulations! (link)

Apr, 2017: Jiayuan's paper on continuous membrane-assisted crystallization to increase the attainable product quality of pharmaceuticals and design space for operation has been accepted for publication in Industrial & Engineering Chemistry Research. Congratulations! (link)

Apr, 2017: Gabriela and Jiayuan have abstracts accepted for the ISIC conference in Dublin, Ireland. Come to Ireland to learn more about their work on continuous pharmaceutical crystallization!

Mar, 2017: Richard and collaborators receive an ITF Tier 3 Grant of HK$1,400,000 to investigate integrated continuous pharmaceutical manufacturing of a drug application. Co-investigators are Prof. Philip C.L. Kwok (The University of Hong Kong) and Prof. Henry H.Y. Tong (Macao Polytechnic Institute). Congratulations!

Mar, 2017: Richard delivers an invited lecture on "Future directions in the manufacture of (bio)pharmaceuticals: continuous pharmaceutical crystallization and electric-field-assisted protein crystallization" at the Asian Dean's Forum Workshop on Bioengineering at NUS in Singapore.

Nov, 2016: Fei and Yu present their work at the AIChE Annual Meeting in San Francisco.

Nov, 2016: The Lakerveld lab complete a hiking trip followed by a well-deserved dinner in Sai Kung.

Oct, 2016: Yu's paper presenting an optimization-based approach for structural design of self-assembled DNA tiles has been accepted for publication in AIChE Journal. Congratulations! (link)

Sep, 2016: Maryam's book chapter on the past achievements and future trends of photocatalysis has been published by the Royal Society of Chemistry. Congratulations!

Sep, 2016: Kay and Monalisa join the Lakerveld lab for individual research projects. Welcome!

Aug, 2015: Postgraduate student Xiao Hua joins the Lakerveld lab. Welcome!

Aug, 2015: Postgraduate student Kiran Mathew Thomas joins the Lakerveld lab. Welcome!

Aug, 2016: Jonathan presents the results of his undergraduate research project on control of directed self-assembly to CBME faculty and successfully finishes his project. Congratulations!

Aug, 2016: Yoshine successfully finishes her summer International Research Opportunities Program (IROP) project on modeling and optimization of continuous pharmaceutical crystallization. Congratulations!

Jul, 2016: The academic year has been officially closed with a delicious summer BBQ (photo)!

Jul, 2016: Yu and Fei have abstracts accepted for oral presentations at the 2016 AIChE Annual Meeting in San Francisco. Come see their talks to learn more about electric-field-assisted protein crystallization, a novel optimization-based method for structural design of self-assembled DNA tiles, or an experimental validation of novel open-loop control methods for directed self-assembly!

Jul, 2016: The group has been awarded a GRF Research Grant from Hong Kong's University Grants Committee of HK$ 675,647 for investigating novel methods to improve control over protein crystallization. Congratulations!

Jun, 2016: Yoshine joins the Lakerveld lab from MIT for a summer International Research Opportunities Program (IROP). Welcome!

Jun, 2016: Maria joins the Lakerveld lab from University of Indonesia for an International Summer Internship. Welcome!

Jun, 2016: Maryam's paper on the model-based optimization of a photocatalytic reactor with light-emitting diodes has been accepted for publication in Chemical Engineering & Technology. Congratulations! (link)

May, 2016: Mickey and Aaron successfully finalized their individual undergraduate research project. Congratulations!

Apr, 2016: The Lakerveld lab conquers the Clear Water Bay Country Park with a 3-hour hiking session!

Jan, 2016: Winnie, Jonathan, and Varun join the Lakerveld Lab for individual undergraduate research projects on continuous pharmaceutical crystallization and directed self-assembly. Welcome!

Dec, 2015: Richard delivers an invited lecture on continuous crystallization of pharmaceuticals at the 2015 Collaborative Conference on Crystal Growth in Hong Kong.

Dec, 2015: A paper co-authored by Richard and co-workers from Purdue, TU Delft, and KU Leuven on a novel automated method to rapidly dissolve small crystals using microwaves during batch pharmaceutical crystallization has appeared in Crystal Growth and Design. You can find our paper here.

Nov, 2015: The Lakerveld lab celebrates its one-year anniversary with a BBQ at the sea front. Congratulations to Yu Gao for bringing into practice one of the newly launched HKUST official core values by managing to put 8 pieces of meat on a single stick ("Can-do Spirit")!

Nov, 2015: Maryam presents her work at the 2015 AIChE Annual Meeting in Salt Lake City (USA) and at the 21st AOTs in San Diego (USA).

Sep, 2015: Maryam presents her work at the 10th European Congress of Chemical Engineering in Nice (France).

Sep, 2015: Aaron and Mickey join the Lakerveld Lab for an undergraduate research project on continuous pharmaceutical crystallization. Welcome!

Sep, 2015: A paper authored by Richard and co-workers from MIT on the automated plant-wide control of the world's first fully integrated continuous pharmaceutical pilot plant has appeared in a special issue of Organic Process Research Development. The special issue features innovative ideas and technologies to address challenges in chemical and pharmaceutical development. You can read the introduction to the special issue here and find our paper here.

Aug, 2015: The Lakerveld Lab moves into their new home: a brand new office and laboratory space!

Aug, 2015: Postgraduate student Gabriela Hadiwinoto joins the Lakerveld lab. Welcome!

Aug, 2015: Postgraduate student Jiayuan Wang joins the Lakerveld lab. Welcome!

Jul, 2015: Richard has been awarded Outstanding Reviewer Status by Elsevier for his reviews completed for Chemical Engineering & Processing: Process Intensification in the past two years

May, 2015: Maryam's abstract has been accepted for presentation at the ECCE10-ECAB3-EPIC5 to be held in Nice in September. Congratulations!

Apr, 2015: Dr. Fei Li joins the Lakerveld lab as a Postdoctoral Associate. Welcome!

Feb, 2015: A paper co-authored by Richard and co-workers from MIT on the dynamic modeling of directed self-assembly via a novel adaptive finite state projection appears online in Industrial & Engineering Chemistry Research.(link)

Jan, 2015: A paper co-authored by Richard and co-workers from MIT and Berkeley on plant-wide model predictive control of a continuous pharmaceutical process has been accepted for an oral presentation at the 2015 American Control Conference. A pre-print of the paper can be found here.

Dec, 2014: Richard receives the Novartis-MIT Enabling Control System Award for his contribution to the first end-to-end integrated continuous pharmaceutical pilot plant (...and since it has been crafted very beautifully, have a look at the photo!).

Oct, 2014: Postgraduate student Gao Yu joins the Lakerveld lab. Welcome!

Oct, 2014: Richard Lakerveld joins the CBE department of Hong Kong University of Science and Technology as an Assistant Professor.

Vacancies

Postdoctoral Associate

We have currently no open positions for postdoctoral associate.

Postgraduate Students

Vacancies for fully funded postgraduate positions are available (PhD or MPhil)! If you have shown academic excellence at a reputable university, are highly motivated, and you have an interest in Chemical Engineering in general, and in the research of our group in particular, please contact Prof. Lakerveld for enquiries.

HKUST is a modern, English-speaking, top-ranked University in Asia. HKUST’s School of Engineering consistently ranks among the top 25 programs in the world. Prof. Lakerveld’s research interests are in the field of Process Systems Engineering. In particular, the focus of the group is on the design and control of processes that involve the production of structured materials. Such processes are typically driven by crystallization or directed self-assembly. Research interests span from controlled assembly of individual building blocks into specific structures on a small scale to optimal integration of unit operations into continuous pharmaceutical manufacturing systems on a large scale.

Candidates should have a BEng or MSc degree (or equivalent) in chemical engineering or related discipline. Sufficient proficiency in the English language is required as demonstrated by an internationally recognized English test score. Extracurricular activities and international exposure are appreciated.

Outstanding applicants will be considered for the highly generous and prestigious Hong Kong PhD Fellowship Scheme. Please see the following link for details on the HKPFS or please contact Prof. Lakerveld for enquiries.

Contact

Richard Lakerveld

The Hong Kong University of Science and Technology

Department of Chemical and Biological Engineering

Clear Water Bay, Hong Kong, China

Email: r.lakerveld@ust.hk

Room: CYT2003

Phone: (852) 3469 2217

Please see Maps and Directions for more details on campus accessibility